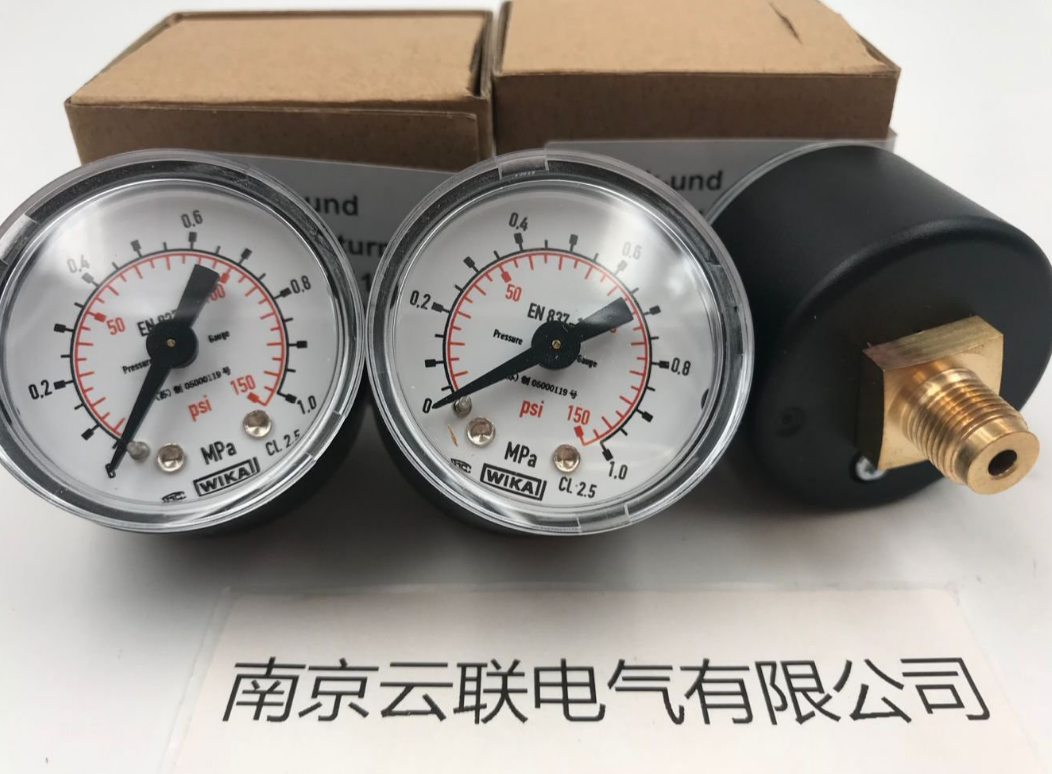

解析工业液压场景痛点,高精度耐震不锈钢压力表的适配优势

1. 高精度耐震不锈钢压力表,工业液压场景专用!0.2/0.4级精准测量,304/316不锈钢材质防腐蚀耐高温,内置阻尼液防抖动,适配高频振动、腐蚀性介质等恶劣场景,解决液压监测读数偏差、设备易损坏痛点,长寿命、易安装,降低企业运维成本,适配工程机械、冶金、矿山等多领域。

详细介绍

解析工业液压场景痛点,高精度耐震不锈钢压力表的适配优势

工业液压系统广泛应用于工程机械、冶金、机床、矿山、石油化工等多个领域,是工业生产的核心动力来源。但在实际运行过程中,液压系统的压力监测常常面临诸多痛点,比如振动导致压力表读数不准、介质腐蚀导致设备损坏、精度不足影响生产质量、恶劣环境导致设备寿命缩短等,这些痛点不仅影响液压设备的正常运行,还可能增加企业的生产风险与运维成本。而高精度耐震不锈钢压力表,针对性解决工业液压场景的各类痛点,凭借其专属适配优势,成为破解行业难题的理想选择。

痛点一:工业液压设备振动剧烈,压力表读数偏差大、易损坏。工业液压设备运行时,液压泵、电机、液压缸等部件会产生持续的振动,部分设备的振动频率可达数百赫兹,普通压力表的内部机芯由精密齿轮、游丝等部件组成,振动会导致这些部件相互摩擦、松动,进而出现指针抖动、读数偏差过大的情况,严重时还会导致机芯损坏、压力表报废。尤其是在工程机械、矿山设备等高频振动场景中,普通压力表的使用寿命往往不足3个月,需要频繁更换,不仅增加了运维成本,还可能因更换不及时导致压力监测中断,引发设备故障。

针对这一痛点,高精度耐震不锈钢压力表采用了专属的耐震结构设计。其内部填充硅油或甘油阻尼液,阻尼液具有良好的缓冲作用,能够有效吸收设备振动产生的冲击力,减少机芯部件的晃动,确保指针平稳运行,读数清晰准确。同时,压力表机芯采用强化精密结构,齿轮、游丝等部件选用高强度耐磨材料,经过特殊热处理工艺加工,提升了部件的抗振动能力与使用寿命,即便在高频振动的液压场景中,也能保持稳定的测量性能,使用寿命可达普通压力表的3-5倍,大幅降低了企业的运维成本。

痛点二:液压介质腐蚀、高温环境,导致压力表材质老化、损坏。工业液压系统中使用的液压油,部分含有腐蚀性添加剂,同时液压设备运行时会产生一定的热量,导致系统温度升高,部分场景的液压油温度可达150℃以上。普通碳钢压力表或塑料压力表,在腐蚀性液压油与高温环境的双重作用下,表壳、接头等部件易生锈、腐蚀、老化,甚至出现漏油、破损的情况,不仅影响压力表的正常使用,还可能污染液压介质,损坏液压系统的其他部件。

高精度耐震不锈钢压力表针对性解决了腐蚀与高温难题,通体采用304或316不锈钢材质打造。304不锈钢具备良好的耐腐蚀性、耐高温性与机械强度,能够抵御普通液压油、水汽、灰尘等介质的侵蚀,适配温度范围为-40℃至120℃,满足大多数工业液压场景的使用需求;316不锈钢则在304不锈钢的基础上,添加了钼元素,进一步提升了耐腐蚀性与耐高温性能,适配温度范围为-40℃至150℃,可用于含腐蚀性液压油、高温高压的苛刻液压场景,比如化工、石油领域的液压系统。不锈钢材质的应用,不仅有效延长了压力表的使用寿命,还避免了材质老化、腐蚀对液压系统造成的污染与损坏。

痛点三:压力测量精度不足,影响生产质量与设备安全。工业液压系统对压力控制的精度要求极高,不同场景的精度要求存在差异,比如精密液压机床的压力精度要求需达到±0.01MPa,液压成型设备的压力精度要求需达到±0.05MPa。普通工业压力表的精度等级多为1.0级或2.5级,无法满足高精度液压场景的测量需求,读数偏差过大可能导致产品加工精度不合格、设备动作失灵,甚至引发管路爆裂、设备损坏等安全事故。

高精度耐震不锈钢压力表以高精度为核心优势,精度等级可达到0.2级或0.4级,最小分度值可达到0.01MPa,能够精准捕捉液压系统内部的压力变化,实时反馈真实的压力数据。其内部采用高精度弹性元件与精密机芯结构,弹性元件经过严格的校准与测试,确保压力感应的准确性;机芯采用精密齿轮传动结构,减少了传动误差,进一步提升了测量精度。同时,压力表表盘采用高清刻度设计,搭配宽大的指针,方便操作人员快速、准确读取数据,为设备参数调整、故障排查提供可靠依据,有效提升生产质量与设备运行安全性。

痛点四:工业现场环境恶劣,压力表防护性能不足。工业液压设备多运行在户外、车间等恶劣环境中,面临灰尘、水汽、油污、碰撞等多种因素的影响,普通压力表的防护性能较差,灰尘、水汽易进入内部,导致机芯损坏、读数偏差;油污附着在表盘上,影响读数清晰度;碰撞则可能导致表壳、玻璃破损,影响设备正常使用。

为适配恶劣的工业现场环境,高精度耐震不锈钢压力表配备了全面的防护设计。表盘采用钢化防爆玻璃,不仅透明度高,还能有效防止碰撞、冲击导致的玻璃破损,同时具备良好的防尘、防水性能;表壳采用密封式结构设计,搭配优质密封件,防护等级可达IP65,能够有效抵御灰尘、水汽、油污的侵蚀,避免内部元件损坏;表壳表面经过抛光、喷塑处理,不仅美观大方,还能提升耐磨性与抗腐蚀性,减少碰撞对设备的损坏。此外,压力表的接口采用密封式螺纹设计,安装后能够有效防止液压油泄漏,进一步提升了设备的防护性能。

除了针对性解决上述痛点,高精度耐震不锈钢压力表还具备诸多实用的适配优势。其接口采用M20×1.5标准螺纹设计,适配绝大多数工业液压设备的接口规格,安装便捷,可直接与液压管路、液压泵站连接,无需额外适配配件;部分型号支持定制,可根据不同液压场景的压力范围、安装方式、表盘大小等需求,定制专属的压力表产品,满足个性化使用需求;同时,该类压力表的校准周期较长,通常为12个月,相较于普通压力表的6个月校准周期,进一步降低了企业的运维成本与工作量。

在实际应用中,高精度耐震不锈钢压力表已成为各类工业液压场景的首选压力监测设备。无论是高频振动的工程机械、高温高压的冶金设备,还是精密的液压机床、腐蚀性较强的化工液压系统,该压力表都能稳定发挥测量作用,针对性解决各类场景痛点,为液压设备的平稳运行提供可靠保障。随着工业液压技术的不断发展,各类液压场景的痛点将更加突出,高精度耐震不锈钢压力表也将通过持续的技术创新,不断优化产品性能,为行业发展提供更优质的压力监测解决方案。

#耐震不锈钢压力表 #高精度压力表 #工业液压痛点 #液压压力表适配 #不锈钢耐震表

Analysis of Pain Points in Industrial Hydraulic Scenarios and Adaptive Advantages of High-Precision Shock-Resistant Stainless Steel Pressure Gauges

Industrial hydraulic systems are widely used in construction machinery, metallurgy, machine tools, mining, petrochemicals and other fields, serving as the core power source for industrial production. However, in actual operation, pressure monitoring of hydraulic systems often faces numerous pain points, such as inaccurate pressure gauge readings caused by vibration, equipment damage due to medium corrosion, compromised production quality from insufficient precision, and shortened equipment service life in harsh environments. These pain points not only affect the normal operation of hydraulic equipment but also may increase the production risks and operation and maintenance costs of enterprises. In contrast, high-precision shock-resistant stainless steel pressure gauges address various pain points in industrial hydraulic scenarios in a targeted manner and have become an ideal solution to industry challenges by virtue of their exclusive adaptive advantages.

Pain Point 1: Severe Vibration of Industrial Hydraulic Equipment Leading to Large Reading Deviations and Easy Damage of Pressure Gauges

During the operation of industrial hydraulic equipment, components such as hydraulic pumps, motors and hydraulic cylinders generate continuous vibration, and the vibration frequency of some equipment can reach several hundred hertz. The internal movement of ordinary pressure gauges consists of precision components such as gears and hairsprings. Vibration causes friction and loosening between these components, leading to pointer jitter and excessive reading deviations. In severe cases, it may even result in movement damage and pressure gauge scrapping. Especially in high-frequency vibration scenarios such as construction machinery and mining equipment, the service life of ordinary pressure gauges is often less than 3 months, requiring frequent replacement. This not only increases operation and maintenance costs but also may cause interruptions in pressure monitoring due to untimely replacement, triggering equipment failures.

To address this pain point, high-precision shock-resistant stainless steel pressure gauges adopt an exclusive shock-resistant structural design. Their interior is filled with silicone oil or glycerin damping fluid, which has a good buffering effect. It can effectively absorb the impact force generated by equipment vibration, reduce the shaking of movement components, ensure stable pointer operation and clear and accurate readings. At the same time, the pressure gauge movement adopts a reinforced precision structure, and components such as gears and hairsprings are made of high-strength wear-resistant materials and processed through special heat treatment processes, which improves the vibration resistance and service life of the components. Even in high-frequency vibration hydraulic scenarios, it can maintain stable measurement performance with a service life 3 to 5 times that of ordinary pressure gauges, greatly reducing the operation and maintenance costs of enterprises.

Pain Point 2: Corrosion of Hydraulic Medium and High-Temperature Environment Causing Material Aging and Damage of Pressure Gauges

Some hydraulic oils used in industrial hydraulic systems contain corrosive additives. Meanwhile, heat is generated during the operation of hydraulic equipment, leading to an increase in system temperature, and the temperature of hydraulic oil in some scenarios can exceed 150℃. Ordinary carbon steel or plastic pressure gauges are prone to rust, corrosion and aging of shell, joints and other components under the combined action of corrosive hydraulic oil and high-temperature environment, and even oil leakage and damage may occur. This not only affects the normal use of pressure gauges but also may pollute the hydraulic medium and damage other components of the hydraulic system.

High-precision shock-resistant stainless steel pressure gauges solve the problems of corrosion and high temperature in a targeted manner and are fully made of 304 or 316 stainless steel. 304 stainless steel has good corrosion resistance, high temperature resistance and mechanical strength, which can resist the erosion of ordinary hydraulic oil, water vapor, dust and other media. It has an adaptive temperature range of -40℃ to 120℃, meeting the usage requirements of most industrial hydraulic scenarios. On the basis of 304 stainless steel, 316 stainless steel is added with molybdenum element, which further improves its corrosion resistance and high temperature resistance with an adaptive temperature range of -40℃ to 150℃. It can be used in harsh hydraulic scenarios with corrosive hydraulic oil, high temperature and high pressure, such as hydraulic systems in the chemical and petroleum fields. The application of stainless steel not only effectively extends the service life of pressure gauges but also avoids pollution and damage to the hydraulic system caused by material aging and corrosion.

Pain Point 3: Insufficient Pressure Measurement Precision Affecting Production Quality and Equipment Safety

Industrial hydraulic systems have extremely high precision requirements for pressure control, and the precision requirements vary in different scenarios. For example, the pressure precision requirement of precision hydraulic machine tools needs to reach ±0.01MPa, and that of hydraulic forming equipment needs to reach ±0.05MPa. The precision grade of ordinary industrial pressure gauges is mostly Grade 1.0 or Grade 2.5, which cannot meet the measurement requirements of high-precision hydraulic scenarios. Excessive reading deviations may lead to unqualified product processing precision, equipment action failure, and even safety accidents such as pipeline burst and equipment damage.

High-precision shock-resistant stainless steel pressure gauges take high precision as their core advantage, with a precision grade of up to Grade 0.2 or Grade 0.4 and a minimum graduation value of 0.01MPa. They can accurately capture the pressure changes

下一篇:没有了