解析温度变送器:原理、结构与核心优势

在工业自动化测控领域,温度是最基础、最核心的监测参数之一,无论是化工生产的反应釜温控、电力系统的设备散热监测,还是暖通行业的环境调节,都离不开精准、稳定的温度数据支撑。而温度变送器作为连接温度传感器与测控系统的“桥梁”,承担着信号转换、传输与优化的关键职责,其性能直接决定了整个测温系统的精准度与可靠性。今天,我们就从原理、结构、核心优势三个维度,全面解析温度变送器的核心逻辑,带大家读懂这款工业自动化领域的“基础测控神器”。

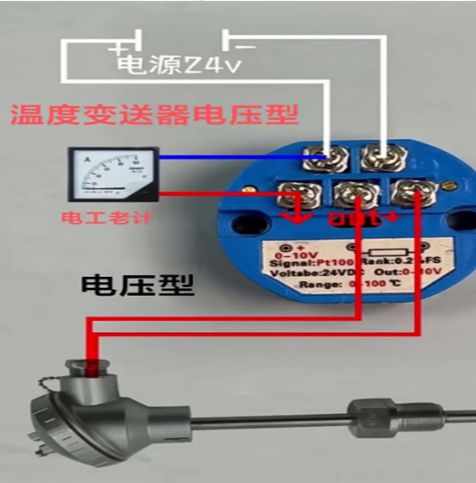

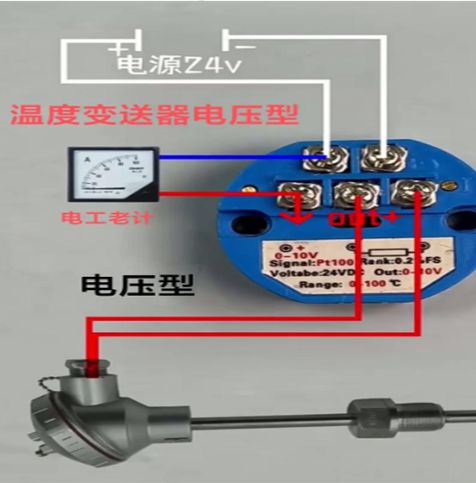

温度变送器的核心工作原理,本质是“信号转换与放大”。不同于直接输出传感信号的温度传感器(如热电偶、热电阻),温度变送器本身不具备直接测温功能,而是接收传感器输出的微弱电信号(如毫伏级电压、欧姆级电阻),通过内部的信号调理电路、放大电路、转换电路,将其转换为工业标准电信号(4-20mA直流电流信号、0-10V直流电压信号等),再传输至PLC、DCS等测控终端,实现温度数据的远程监测、显示与调控。

从工作逻辑来看,温度变送器的信号转换过程分为三个核心步骤:首先是信号采集,变送器通过接线端子与温度传感器连接,精准捕捉传感器因温度变化产生的微弱信号,这一步要求接线稳定,避免接触不良导致的信号失真;其次是信号调理,内部滤波电路会过滤掉工业环境中的电磁干扰、杂波信号,放大电路则将微弱信号放大至可处理范围,确保信号的稳定性;最后是信号转换,通过模数转换芯片,将模拟信号转换为标准数字信号或模拟标准信号,满足远距离传输的需求——其中4-20mA电流信号因抗干扰能力强、传输距离远(可达数百米),成为工业领域应用最广泛的标准信号。

从结构组成来看,温度变送器主要分为四个核心部件,各部件协同工作,保障设备稳定运行。一是外壳,采用不锈钢、铸铝等耐腐蚀、抗冲击的材质,密封等级可达IP65及以上,能有效抵御工业环境中的粉尘、水汽、腐蚀性气体侵蚀,适配高低温、强震动等恶劣工况;二是接线端子,负责连接温度传感器与测控终端,采用防松动设计,避免因接线脱落导致设备故障;三是核心电路模块,这是变送器的“大脑”,包含信号调理、放大、转换等电路,采用高精度芯片,确保信号转换的精准度,部分高端产品还集成了智能校准模块,可通过软件远程校准,减少现场调试工作量;四是显示模块(可选),部分变送器配备LCD显示屏,可实时显示测量温度、信号状态等信息,方便现场工作人员查看。

相较于传统测温设备,温度变送器具备三大核心优势,使其在工业自动化领域得到广泛应用。其一,精准度高,误差范围小,主流产品的测量精度可达±0.1℃~±0.5℃,能满足高精度测温需求,如医药、电子等对温度控制要求严苛的行业;其二,抗干扰能力强,通过内部滤波电路与屏蔽设计,可有效抵御工业现场的电磁干扰、电压波动等影响,确保信号传输稳定,避免因信号失真导致的测控失误;其三,安装便捷、适配性广,可与热电偶、热电阻等多种温度传感器配套使用,支持壁挂式、导轨式、插入式等多种安装方式,适配不同的工业场景,同时体积小巧,不占用过多安装空间。

此外,随着工业自动化技术的不断升级,温度变送器也朝着智能化、数字化方向发展。智能型温度变送器集成了微处理器,可实现温度数据的实时采集、分析与存储,支持HART、Modbus等通讯协议,能与测控系统实现双向通讯,方便工作人员远程监控设备运行状态、调整参数、排查故障;部分产品还具备自诊断功能,可自动检测设备故障(如传感器断线、电路故障等),并输出报警信号,降低设备维护成本。

作为工业自动化测控系统中的基础部件,温度变送器的性能直接影响整个生产流程的稳定性与安全性。无论是普通工业场景的常规测温,还是高端领域的高精度测控,温度变送器都凭借其精准、稳定、便捷的优势,成为不可或缺的核心设备。了解其原理、结构与优势,有助于企业根据自身需求选择合适的产品,优化测温系统,提升生产效率与产品质量。

#温度变送器 #信号转换 #工业自动化 #精准测温 #智能变送器

An Analysis of Temperature Transmitters: Principles, Structure and Core Advantages

In the field of industrial automation measurement and control, temperature is one of the most fundamental and core monitoring parameters. Whether it is the temperature control of reaction kettles in chemical production, the heat dissipation monitoring of power system equipment, or the environmental regulation in the HVAC industry, all rely on accurate and stable temperature data support. As a "bridge" connecting temperature sensors and measurement & control systems, temperature transmitters undertake the key responsibilities of signal conversion, transmission and optimization, and their performance directly determines the accuracy and reliability of the entire temperature measurement system. Today, we will comprehensively analyze the core logic of temperature transmitters from three dimensions: principles, structure and core advantages, helping you understand this "basic measurement and control tool" in the field of industrial automation.

The core working principle of a temperature transmitter is essentially signal conversion and amplification. Different from temperature sensors (such as thermocouples and thermal resistors) that directly output sensing signals, temperature transmitters themselves do not have the function of direct temperature measurement. Instead, they receive weak electrical signals (such as millivolt-level voltage and ohm-level resistance) output by sensors, and convert them into industrial standard electrical signals (4-20mA DC current signal, 0-10V DC voltage signal, etc.) through internal signal conditioning circuits, amplification circuits and conversion circuits. The signals are then transmitted to measurement & control terminals such as PLC and DCS to realize remote monitoring, display and regulation of temperature data.

From the perspective of working logic, the signal conversion process of a temperature transmitter is divided into three core steps: first, signal acquisition. The transmitter is connected to the temperature sensor through terminal blocks to accurately capture the weak signal generated by the sensor due to temperature changes. This step requires stable wiring to avoid signal distortion caused by poor contact. Second, signal conditioning. The internal filter circuit filters out electromagnetic interference and clutter signals in the industrial environment, and the amplification circuit amplifies the weak signal to a processable range to ensure signal stability. Third, signal conversion. The analog signal is converted into a standard digital signal or analog standard signal through an analog-to-digital conversion chip to meet the needs of long-distance transmission. Among them, the 4-20mA current signal has become the most widely used standard signal in the industrial field due to its strong anti-interference ability and long transmission distance (up to hundreds of meters).

In terms of structural composition, a temperature transmitter is mainly composed of four core components, which work together to ensure the stable operation of the equipment. First, the shell, made of corrosion-resistant and impact-resistant materials such as stainless steel and cast aluminum, with a protection grade of IP65 or above. It can effectively resist the erosion of dust, water vapor and corrosive gas in the industrial environment, and is suitable for harsh working conditions such as high and low temperatures and strong vibrations. Second, the terminal blocks, responsible for connecting the temperature sensor and the measurement & control terminal, adopt an anti-loosening design to avoid equipment failure caused by wiring falling off. Third, the core circuit module, the "brain" of the transmitter, including signal conditioning, amplification, conversion and other circuits, uses high-precision chips to ensure the accuracy of signal conversion. Some high-end products are also integrated with an intelligent calibration module, which can be remotely calibrated through software to reduce on-site debugging work. Fourth, the display module (optional). Some transmitters are equipped with an LCD screen that can display measured temperature, signal status and other information in real time, for the convenience of on-site staff to check.

Compared with traditional temperature measurement equipment, temperature transmitters have three core advantages, making them widely used in the field of industrial automation. First, high accuracy with a small error range. The measurement accuracy of mainstream products can reach ±0.1℃ ~ ±0.5℃, which can meet the requirements of high-precision temperature measurement, such as the pharmaceutical and electronic industries with strict temperature control requirements. Second, strong anti-interference ability. Through internal filter circuits and shielding design, it can effectively resist the influence of electromagnetic interference and voltage fluctuations in the industrial field, ensure stable signal transmission, and avoid measurement and control errors caused by signal distortion. Third, easy installation and wide adaptability. It can be used with a variety of temperature sensors such as thermocouples and thermal resistors, supports multiple installation methods such as wall-mounted, rail-mounted and plug-in, and is suitable for different industrial scenarios. At the same time, it is compact in size and does not occupy too much installation space.

In addition, with the continuous upgrading of industrial automation technology, temperature transmitters are also developing towards intellectualization and digitalization. Intelligent temperature transmitters are integrated with microprocessors, which can realize real-time acquisition, analysis and storage of temperature data, support communication protocols such as HART and Modbus, and achieve two-way communication with measurement & control systems, facilitating staff to remotely monitor equipment operation status, adjust parameters and troubleshoot faults. Some products also have a self-diagnosis function, which can automatically detect equipment faults (such as sensor disconnection, circuit failure, etc.) and output alarm signals, reducing equipment maintenance costs.

As a basic component in the industrial automation measurement and control system, the performance of temperature transmitters directly affects the stability and safety of the entire production process. Whether it is conventional temperature measurement in ordinary industrial scenarios or high-precision measurement and control in high-end fields, temperature transmitters have become an indispensable core equipment by virtue of their advantages of high precision, stability and convenience. Understanding their principles, structure and advantages helps enterprises select suitable products according to their own needs, optimize the temperature measurement system, and improve production efficiency and product quality.

#TemperatureTransmitter #SignalConversion #IndustrialAutomation #PrecisionTemperatureMeasurement