详细介绍

综上所述,气动调节阀和减压阀在调节精度、响应速度、压力调节范围、流量特性以及可靠性和维护等性能特点上存在明显差异。在实际应用中,应根据具体的工况要求和性能需求,合理选择气动调节阀或减压阀,以达到最佳的控制效果和经济效益。# 气动调节阀,减压阀,性能特点,调节精度,响应速度

Differences between Pneumatic Control Valves and Pressure Reducing Valves: Comparative Analysis of Performance Characteristics

Pneumatic control valves and pressure reducing valves have their own advantages in the field of industrial fluid control, and their performance characteristics determine their scope of application and working effect. By comparing and analyzing the performance characteristics of the two, we can have a clearer understanding of their differences and provide powerful references for selection and use in practical applications.

From the perspective of adjustment accuracy, pneumatic control valves have extremely high adjustment accuracy. It can achieve precise displacement of the valve core based on small signal changes emitted by the control system, thereby accurately adjusting parameters such as flow rate, pressure, and temperature of the medium. This is due to the collaborative work of its advanced actuators and locators and other components. For example, in some high-precision chemical production processes, flow control accuracy of ± 1% or even higher is required, and pneumatic control valves can well meet this demand. Although pressure reducing valves can also achieve stable regulation of outlet pressure, their regulation accuracy is relatively low. Its main purpose is to stabilize the pressure within a certain range, and its ability to control small fluctuations in pressure is limited. Generally, the stability accuracy of outlet pressure is around ± 5%, which can meet the usage requirements in some situations where pressure accuracy is not particularly high.

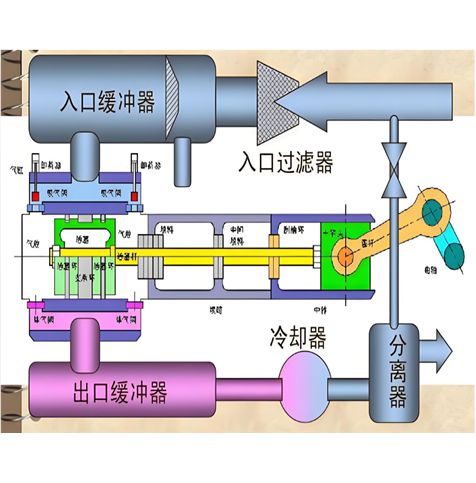

In terms of response speed, pneumatic control valves exhibit fast response characteristics. Due to its use of compressed air as a power source, the actuator can quickly move and respond to control signals. In some working conditions that require rapid adjustment, such as boiler combustion control, when the load changes, the pneumatic control valve can adjust the valve opening in a very short time, change the fuel supply, and quickly restore the stability of the boiler's operating parameters. In contrast, the response speed of pressure reducing valves is relatively slow. It mainly relies on changes in medium pressure and the mechanical balance of its own structure to achieve regulation. The regulation process is relatively slow, usually taking several seconds or even longer to reach a new stable state, which is determined by its working principle and structural characteristics.

In terms of pressure regulation range, pneumatic control valves and pressure reducing valves are also different. The pressure regulation range of pneumatic control valves is usually related to the working pressure of the system. It can regulate the medium pressure within a wide pressure range, but mainly focuses on dynamic control and regulation of pressure. The pressure regulation range of the pressure reducing valve is one of its important performance indicators, and different models of pressure reducing valves have different inlet and outlet pressure regulation ranges. Generally speaking, pressure reducing valves can reduce higher inlet pressure to lower outlet pressure and maintain stable outlet pressure within a certain range of pressure fluctuations. Their adjustment range can vary from low pressure to medium high pressure to adapt to different application scenarios.

In addition, there are differences in the traffic characteristics between the two. The flow characteristics of pneumatic control valves are mainly determined by the shape of the valve core, commonly including linear flow characteristics, equal percentage flow characteristics, etc. The linear flow characteristic is suitable for situations where the system pressure is stable and the adjustment range is narrow; The equal percentage flow characteristic is suitable for situations where the system pressure changes greatly and the adjustment range is wide, and can achieve a relatively uniform adjustment effect at different opening degrees. The flow characteristics of a pressure reducing valve are relatively simple, mainly to ensure that the outlet pressure can remain stable within a certain flow range. The relationship between flow and pressure is relatively fixed, and it does not have the diverse flow regulation characteristics of pneumatic regulating valves.

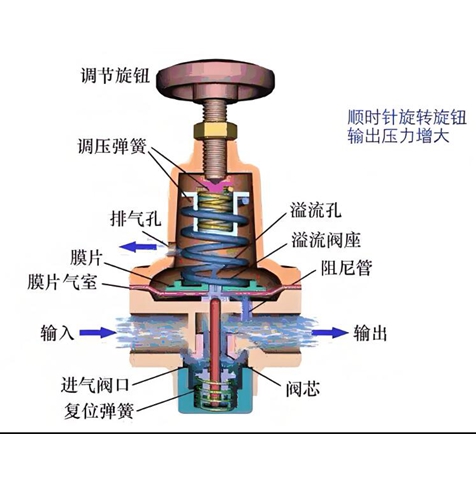

In terms of reliability and maintenance, pneumatic control valves require high maintenance due to their relatively complex structure, including multiple components and accessories. It is necessary to regularly check the working status of components such as actuators and positioners to ensure the transmission of control signals and the accuracy of valve actions. The structure of a pressure reducing valve is relatively simple and easy to maintain. Generally, only the performance of key components such as springs and diaphragms needs to be checked regularly, and impurities inside the valve body need to be cleaned to ensure the normal operation of the valve.

In summary, there are significant differences in performance characteristics between pneumatic control valves and pressure reducing valves, such as regulation accuracy, response speed, pressure regulation range, flow characteristics, reliability, and maintenance. In practical applications, pneumatic control valves or pressure reducing valves should be selected reasonably according to specific working conditions and performance requirements to achieve the best control effect and economic benefits. #Pneumatic control valve, pressure reducing valve, performance characteristics, adjustment accuracy, response speed