详细介绍

The difference between solenoid valves and pneumatic valves - applicable environment and safety

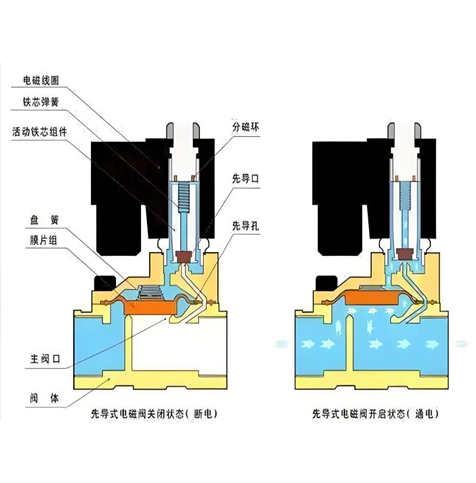

Electromagnetic valves have certain requirements for the working environment. Due to the presence of electrical components inside, special protective measures are required when used in humid, dusty, flammable, and explosive environments. For example, in flammable and explosive environments, it is necessary to use explosion-proof solenoid valves, whose structure is specially designed to prevent explosions caused by electric sparks and other factors. Meanwhile, the working temperature range of solenoid valves is relatively narrow, and temperatures that are too high or too low may affect their performance and lifespan.

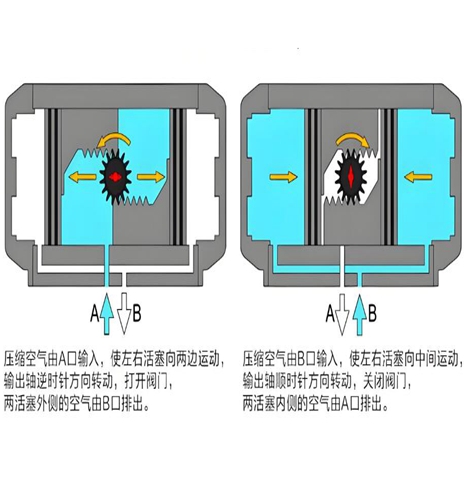

Pneumatic valves have good environmental adaptability. Because its working medium is compressed air and there is no risk of electrical components generating electric sparks in hazardous environments, it has significant advantages in harsh environments such as flammable, explosive, humid, and dusty environments. Pneumatic valves are widely used in hazardous areas of industries such as petroleum and chemical. In addition, the working temperature range of pneumatic valves is relatively wide, and they can operate stably under different temperature conditions.

From a safety perspective, in the event of a power failure, the solenoid valve may maintain its current state or operate according to a preset safety mode; In the event of a gas source failure, pneumatic valves generally use methods such as spring reset based on the structure and design of the valve to keep the valve in a safe position and avoid dangerous situations. However, it should be noted that the air supply system of the pneumatic valve requires regular maintenance to ensure stable supply and cleanliness of the air source, in order to ensure the normal operation and safety of the valve.