详细介绍

WIKA波登管压力表其结构和工作原理是什么?

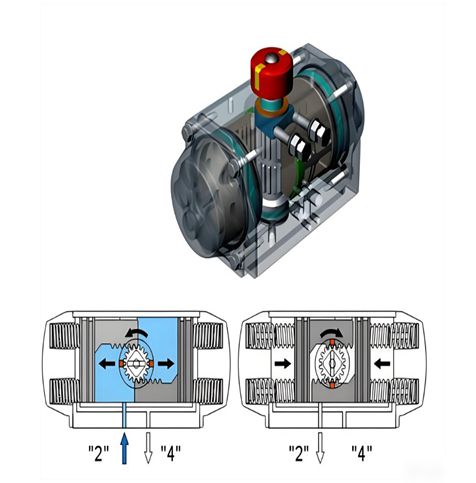

波登管压力表是最常用的机械压力测量仪表。其压力元件通常被称为波登管:它是基于弹性弹簧,c形的,弯曲且具有椭圆形的横截面的管。

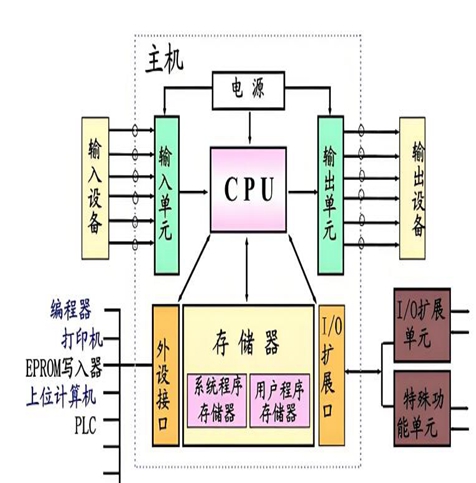

波登管压力表的结构

当波登管的内部空间受压时,横截面朝向圆形改变。在该过程中产生的环向应力增加了C形管的半径。由此,管的末端移动了大约两到三毫米。这个偏转就是压力的量度。压力被转换为位移,这个位移将线性偏转转变为旋转位移,并通过指针使其在刻度上可视。

压力对波登管的影响

波登管的种类

使用C形弯曲的波登管,可以显示高达6MPa的压力。对于更高的压力,可使用螺旋形波登管。根据几何形状、材料和材料厚度的不同,可显示高达700MPa的压力。根据要求,压力元件可选择铜合金、不锈钢或如蒙乃尔等特殊材料制成。

What is the structure and working principle of a WIKA Bourdon tube pressure gauge?

The Bourdon tube pressure gauge is the most commonly used mechanical pressure measuring instrument. Its pressure component is commonly referred to as a Bourdon tube: it is based on an elastic spring, a C-shaped, curved tube with an elliptical cross-section.

Structure of Bourdon tube pressure gauge

When the internal space of the Bourdon tube is compressed, the cross-section changes towards a circular shape. The circumferential stress generated during this process increases the radius of the C-shaped pipe. As a result, the end of the tube moved by approximately two to three millimeters. This deflection is a measure of pressure. Pressure is converted into displacement, which converts linear deflection into rotational displacement and makes it visible on the scale through a pointer.

The influence of pressure on the Bourdon tube

Types of Bourdon tubes

The use of C-shaped curved Bourdon tubes can display pressures up to 6MPa. For higher pressures, spiral bourdon tubes can be used. Depending on the geometric shape, material, and material thickness, a pressure of up to 700MPa can be displayed. According to requirements, pressure components can be made of copper alloy, stainless steel, or special materials such as Monel.