详细介绍

缓冲器的距离调整和使用方法

在各种机械设备中,缓冲器起着至关重要的作用。它能够有效地减少冲击力,保护设备和操作人员的安全。下面我们就来详细了解一下缓冲器的距离调整和使用方法。

一、缓冲器的重要性

缓冲器能够在设备运行过程中,吸收和减缓因运动部件的快速启停、碰撞等产生的冲击力。这不仅可以延长设备的使用寿命,还能降低噪音、提高设备的稳定性和可靠性。对于一些对精度要求较高的设备,缓冲器更是不可或缺的组成部分。

二、缓冲器的分类

常见的缓冲器主要有液压缓冲器和油压缓冲器。液压缓冲器通过液压阻尼的作用对物体进行缓冲减速,具有响应速度快、缓冲效果好等优点。油压缓冲器则利用油的压力来实现缓冲,适用于较大冲击力的场合。

三、缓冲器的距离调整

1. 确定调整需求

在进行距离调整之前,首先需要明确设备的工作要求和运动轨迹。根据不同的应用场景,确定合适的缓冲距离,以确保缓冲器能够在关键时刻发挥作用。

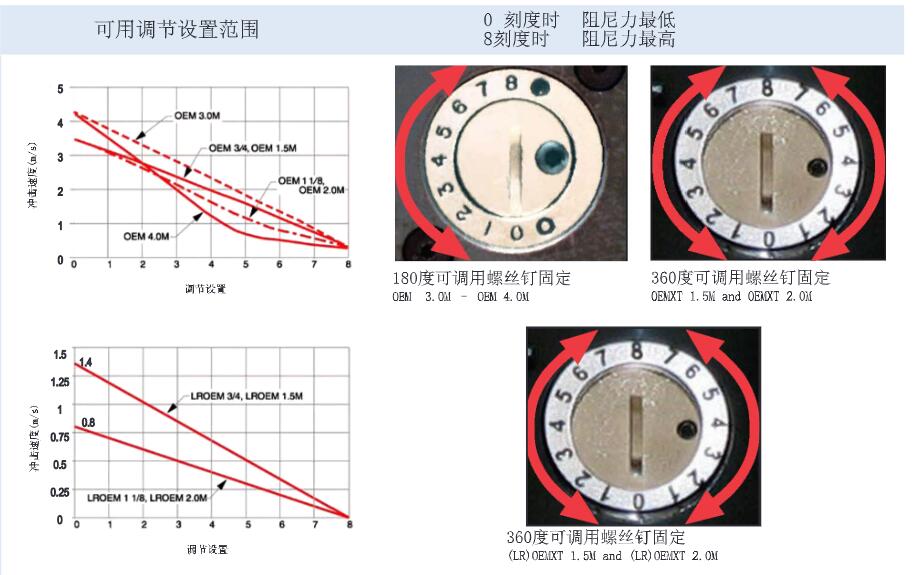

2. 调整方法

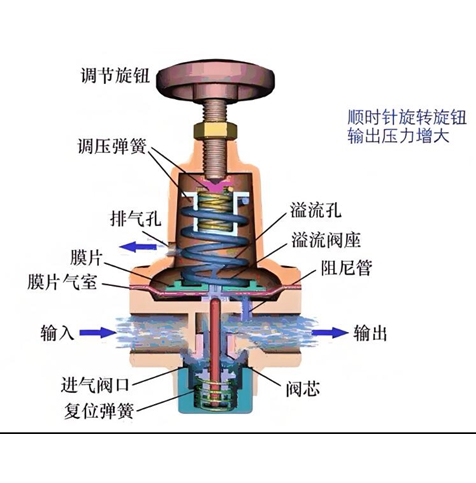

对于液压缓冲器,可以通过调整其内部的阻尼孔大小或液压油的流量来改变缓冲距离。一般来说,增大阻尼孔或减少液压油流量可以增加缓冲距离,反之则减小缓冲距离。油压缓冲器通常可以通过调整其弹簧的预紧力或油压的大小来实现距离调整。

四、缓冲器的使用方法

(一)液压缓冲器使用方法

1. 安装环境

液压缓冲器应安装在干燥、清洁的环境中,避免受到灰尘、水分等杂质的影响。安装时要确保缓冲器的安装位置正确,与运动部件的连接牢固可靠。

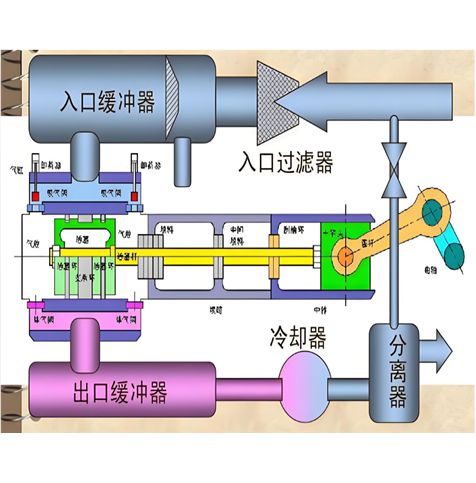

2. 工作原理

当运动部件与液压缓冲器接触时,液压油通过阻尼孔流动,产生阻力,从而减缓运动部件的速度。在这个过程中,液压缓冲器将冲击力转化为热能和液压能,实现缓冲的目的。

3. 注意事项

在使用液压缓冲器时,要定期检查液压油的液位和质量,及时更换变质的液压油。同时,要注意避免缓冲器受到过度的冲击和震动,以免影响其性能和寿命。

(二)油压缓冲器使用方法

1. 常见用途

油压缓冲器广泛应用于工业机械中,如起重机、电梯、输送设备等。它能够在设备运行过程中,有效地吸收和减缓冲击力,保护设备和操作人员的安全。

2. 规范操作

在安装和使用油压缓冲器时,要严格按照说明书的要求进行操作。确保缓冲器的安装位置正确,连接牢固。在使用过程中,要注意观察缓冲器的工作状态,如发现异常情况应及时停机检查。

3. 安全与防火

由于油压缓冲器中含有液压油,因此在使用过程中要注意防火安全。避免缓冲器受到高温、火源等的影响,以免发生火灾事故。同时,要定期检查缓冲器的密封性,防止液压油泄漏。

总之,正确调整缓冲器的距离和掌握其使用方法,对于确保设备的安全运行和延长设备的使用寿命具有重要意义。在实际应用中,我们应根据不同的设备和工作要求,选择合适的缓冲器类型,并严格按照操作规程进行安装和使用。

Distance Adjustment and Usage of Buffer

Buffer plays a crucial role in various mechanical equipment. It can effectively reduce impact force and protect the safety of equipment and operators. Next, let's take a detailed look at the distance adjustment and usage of the buffer.

1、 The Importance of Buffer

Buffer can absorb and reduce the impact force caused by rapid start stop, collision, etc. of moving parts during the operation of the equipment. This can not only extend the service life of the equipment, but also reduce noise, improve the stability and reliability of the equipment. For some devices that require high precision, buffers are an indispensable component.

2、 Classification of buffers

Common buffers mainly include hydraulic buffers and hydraulic buffers. Hydraulic buffers slow down objects through hydraulic damping, which has the advantages of fast response speed and good buffering effect. The hydraulic buffer uses the pressure of oil to achieve buffering, which is suitable for situations with large impact forces.

3、 Adjustment of buffer distance

1. Determine the adjustment requirements

Before adjusting the distance, it is necessary to first clarify the working requirements and motion trajectory of the equipment. Determine the appropriate buffer distance based on different application scenarios to ensure that the buffer can function effectively at critical moments.

2. Adjustment method

For hydraulic buffers, the buffering distance can be changed by adjusting the size of the damping holes inside or the flow rate of hydraulic oil. Generally speaking, increasing the damping hole or reducing the hydraulic oil flow rate can increase the buffering distance, otherwise it can decrease the buffering distance. Oil pressure buffers can usually achieve distance adjustment by adjusting the preload force of their springs or the size of the oil pressure.

4、 How to use the buffer

(1) Instructions for using hydraulic buffer

1. Installation environment

Hydraulic buffers should be installed in a dry and clean environment to avoid being affected by impurities such as dust and moisture. During installation, ensure that the buffer is installed in the correct position and connected firmly and reliably to the moving parts.

2. Working principle

When the moving parts come into contact with the hydraulic buffer, hydraulic oil flows through the damping holes, generating resistance and slowing down the speed of the moving parts. In this process, the hydraulic buffer converts the impact force into thermal energy and hydraulic energy, achieving the purpose of buffering.

3. Precautions

When using hydraulic buffers, it is necessary to regularly check the level and quality of hydraulic oil, and replace deteriorated hydraulic oil in a timely manner. At the same time, it is important to avoid excessive impact and vibration on the buffer to avoid affecting its performance and lifespan.

(2) Instructions for using hydraulic buffer

1. Common uses

Hydraulic buffers are widely used in industrial machinery, such as cranes, elevators, conveying equipment, etc. It can effectively absorb and reduce impact forces during equipment operation, protecting the safety of equipment and operators.

2. Standardized operation

When installing and using hydraulic buffers, strictly follow the instructions in the manual. Ensure that the installation position of the buffer is correct and the connection is firm. During use, pay attention to observing the working status of the buffer. If any abnormal situation is found, stop the machine for inspection in a timely manner.

3. Safety and Fire Prevention

Due to the presence of hydraulic oil in the hydraulic buffer, attention should be paid to fire safety during use. Avoid the buffer from being affected by high temperatures, fire sources, etc., to prevent fire accidents. At the same time, it is necessary to regularly check the sealing of the buffer to prevent hydraulic oil leakage.

In short, correctly adjusting the distance of the buffer and mastering its usage method are of great significance for ensuring the safe operation of the equipment and extending its service life. In practical applications, we should choose the appropriate buffer type according to different equipment and work requirements, and strictly follow the operating procedures for installation and use.