详细介绍

结构决定性能,双作用与单作用气动执行器核心优势深度剖析

气动执行器的性能表现与其结构设计密切相关,双作用与单作用执行器通过不同的动力传输与复位机制,形成了各具特色的优势,在工业控制中承担着不同的功能角色。深入剖析二者的结构优势,对精准选型、提升设备运行效率具有重要意义。

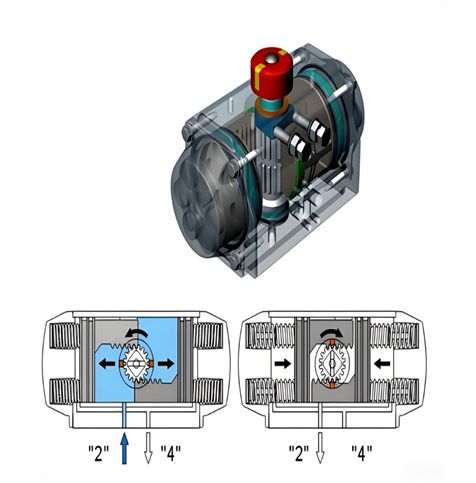

双作用气动执行器采用无弹簧设计,依靠双向气源推动活塞运动实现阀门启闭,这一结构使其具备了动力强劲、响应迅速的核心优势。活塞两侧的气缸容积可根据需求设计,能通过提升气源压力进一步增强推力,适配高压工况下的阀门驱动需求,如在天然气长输管道中,可驱动大口径球阀实现快速截断,保障管道运行安全。同时,无弹簧结构避免了弹簧疲劳、老化带来的性能衰减问题,设备运行稳定性更高,使用寿命可达10万次以上,适合连续运行、频繁切换的工况。

双作用执行器的动作灵活性强,可实现正反转双向调节,且调节精度高,通过配套的定位器可将阀门开度控制在±1%以内,满足精细化工艺控制需求。在自动化生产线中,其快速换向能力可配合PLC控制系统实现精准联动,提升生产流程的自动化水平。此外,双作用执行器的适用介质范围广,可在高温、低温、腐蚀性环境中稳定工作,通过选用不同材质的气缸与密封件,可适配化工、海洋工程、制药等多个行业的特殊需求。

单作用气动执行器的结构核心的复位弹簧,这一设计赋予其安全可靠、节能高效的独特优势。在正常工作时,气源驱动活塞压缩弹簧完成阀门动作,当气源中断时,弹簧弹力释放,驱动活塞复位,确保阀门回归预设安全位,有效避免因阀门失控引发的生产事故。在无人值守的自动化车间、远程控制的油气井场等场景中,单作用执行器的自动复位功能可显著提升系统的安全性与可靠性,降低人工干预成本。

单作用执行器的结构相对简单,零部件数量较少,安装调试便捷,且维护成本低廉。其无需双向气路,气路系统的泄漏风险更低,可减少气源浪费,长期运行节能效果显著。同时,复位弹簧的设计使执行器在断电、断气等紧急情况下无需额外动力即可完成复位,系统配置更简洁,无需配备应急气源装置,降低了设备投入成本。在中小口径阀门、低压工况及对安全性能要求较高的场景中,单作用执行器具有不可替代的优势。

无论是双作用的高效适配,还是单作用的安全可靠,二者均基于结构设计实现了性能优化,为工业控制提供了多样化的驱动解决方案。

#气动执行器 双作用 单作用 结构设计 性能优化 工业控制

Structure determines performance. In-depth analysis of the core advantages of double-acting and single-acting pneumatic actuators

The performance of pneumatic actuators is closely related to their structural design. Double-acting and single-acting actuators, through different power transmission and reset mechanisms, have developed distinct advantages and play different functional roles in industrial control. A deep analysis of the structural advantages of the two types is of great significance for precise selection and improving equipment operational efficiency.

The double-acting pneumatic actuator adopts a springless design, relying on bidirectional air supply to drive the piston movement for valve opening and closing. This structure endows it with core advantages of strong power and rapid response. The cylinder volumes on both sides of the piston can be designed according to requirements, and the thrust can be further enhanced by increasing the air supply pressure, thus adapting to the valve driving needs under high-pressure conditions. For example, in long-distance natural gas pipelines, it can drive large-diameter ball valves to achieve rapid shutoff, ensuring pipeline operation safety. At the same time, the springless structure avoids performance degradation issues caused by spring fatigue and aging, resulting in higher equipment operational stability and a service life of over 100,000 cycles, making it suitable for continuous operation and frequent switching conditions.

Double-acting actuators exhibit strong flexibility in action, enabling bidirectional adjustment for both forward and reverse rotations with high precision. Through the use of a complementary positioner, the valve opening can be controlled within ±1%, meeting the demands of refined process control. In automated production lines, their rapid reversing capability can be integrated with PLC control systems to achieve precise linkage, enhancing the automation level of production processes. Furthermore, double-acting actuators have a wide range of applicable media and can operate stably in high-temperature, low-temperature, and corrosive environments. By selecting cylinders and seals of different materials, they can adapt to the special requirements of various industries such as chemical, marine engineering, and pharmaceutical.

The reset spring, which is the structural core of the single-acting pneumatic actuator, endows it with unique advantages of safety, reliability, energy efficiency, and high performance. During normal operation, the air source drives the piston to compress the spring and complete the valve action. When the air source is interrupted, the spring force is released, driving the piston to reset and ensuring that the valve returns to the preset safe position, effectively avoiding production accidents caused by valve malfunction. In unattended automated workshops, remotely controlled oil and gas well sites, and other scenarios, the automatic reset function of the single-acting actuator can significantly enhance the safety and reliability of the system and reduce the cost of manual intervention.

The structure of a single-acting actuator is relatively simple, with fewer components, convenient installation and debugging, and low maintenance costs. It does not require a bidirectional air circuit, which reduces the risk of leakage in the air circuit system, minimizes waste of air source, and achieves significant energy-saving effects during long-term operation. At the same time, the design of the return spring enables the actuator to reset without additional power in emergency situations such as power failure and air supply interruption, making the system configuration simpler and eliminating the need for an emergency air source device, thereby reducing equipment investment costs. In scenarios involving small and medium-sized valves, low-pressure conditions, and high safety performance requirements, single-acting actuators have irreplaceable advantages.

Whether it's the efficient adaptation of double-acting or the safety and reliability of single-acting, both are based on structural design to achieve performance optimization, providing diversified drive solutions for industrial control.

#Pneumatic Actuator Double-acting Single-acting Structural Design Performance Optimization Industrial Control