详细介绍

#关键词 工业使用

Adjustment method of industrial pressure reducing valve regulator (special operating conditions section)

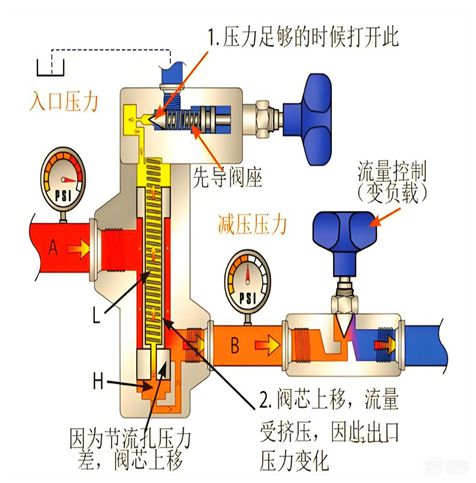

The regulation of industrial pressure reducing valves under special working conditions requires breaking through conventional regulation logic and strengthening the adaptability and risk prediction ability for complex scenarios such as low temperature, high pressure, and high viscosity media. In such scenarios, the pressure reducing valve not only needs to meet the pressure control accuracy (error ≤± 3%), but also needs to resist special risks such as medium phase change and seal failure. For example, in low temperature conditions below -40 ℃, the medium is prone to solidification and cause valve core blockage; In ultra-high pressure conditions above 20MPa, the wear rate of the valve disc is three times that of conventional conditions. Therefore, the adjustment work needs to be based on the core principles of "working condition adaptation, risk pre positioning, and dynamic monitoring", combined with the characteristics of the medium and equipment structure to develop a special plan.

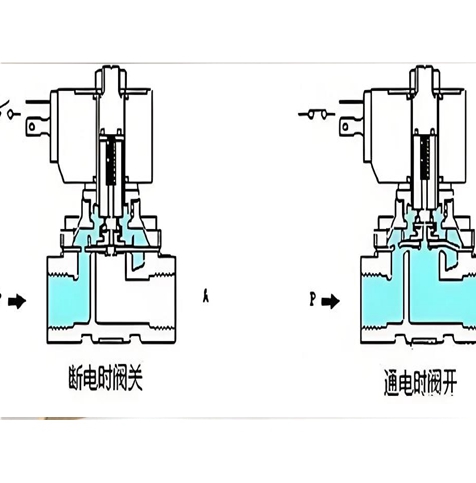

The preparation work before adjustment should highlight the upgrade of "working condition adaptability". In the parameter verification process, in addition to conventional pressure parameters, special parameters such as viscosity (≥ 100mm ²/s is considered high viscosity), pour point, and saturated vapor pressure of the medium need to be confirmed. For example, when transporting high viscosity media such as crude oil, the downstream working pressure needs to be appropriately increased by 5% -8% to compensate for the loss of medium flow resistance. During the equipment adaptation inspection, it is necessary to replace the low-temperature resistant polytetrafluoroethylene seals under low temperature conditions to avoid seal brittleness and cracking; For ultra-high pressure conditions, a forged valve body pressure reducing valve should be selected, and the fit clearance between the valve seat and the valve disc should be checked (should be ≤ 0.02mm) to prevent leakage of high-pressure medium. In terms of instrument configuration, thermocouple pressure transmitters should be selected for high temperature conditions (≥ 400 ℃) to avoid the failure of ordinary pressure gauges due to high temperature; Strong corrosion conditions require the installation of anti-corrosion isolation film for instruments. In terms of tool preparation, specialized equipment such as medium heating devices (for low-temperature solidification media), high-pressure sealing test pumps, viscosity meters, etc. have been added. Emergency pressure relief pipelines need to be added to the operating area, and explosion-proof ventilation equipment (for special working conditions of flammable and explosive media) should be equipped.

The step-by-step adjustment process needs to strengthen "dynamic adaptation" and "risk control". Taking low-temperature working conditions as an example, the first step is to start the medium heating device, raise the medium temperature to 10-15 ℃ above the condensation point, open the bypass valve for pipeline preheating, and avoid the low-temperature medium directly entering the pressure reducing valve and causing component freezing and cracking. When opening the upstream shut-off valve, use the "gradient boosting" method to increase the pressure by 0.5 MPa every 5 minutes until it reaches 50% of the upstream rated pressure. After stabilizing for 10 minutes, continue to increase the pressure. In the initial adjustment stage, for high viscosity media, the opening of the pressure reducing valve should be adjusted to 1.2 times that of the normal operating conditions to avoid medium retention and valve core adhesion; For ultra-high pressure reducing valves, the initial adjustment pressure should be 20% lower than the target value, and a dedicated torque wrench should be used to control the rotation amplitude of the adjusting screw, with no more than 1/16 turn each time. In the fine-tuning stage, the logic of "flow pressure linkage regulation" is introduced to change the medium flow rate by adjusting the downstream flow control valve, while observing the change in outlet pressure. When the flow rate reaches 80% of the rated value and the pressure is stable, the final fine-tuning is carried out. For example, when transporting high viscosity asphalt, it is necessary to first adjust the flow rate to 20m ³/h (50% of the rated flow rate), gradually increase the flow rate to the rated value after the pressure stabilizes, and synchronously adjust the pressure reducing valve to ensure constant pressure.

Precision verification and safety prevention and control require the establishment of a "dynamic monitoring system". The accuracy verification adopts the "multi node monitoring method", and pressure instruments are installed at the inlet, outlet, and downstream 5 meters of the pressure reducing valve to compare the pressure loss at different nodes. If the loss exceeds 0.1 MPa, it is necessary to check whether the pipeline is blocked or whether the valve port is worn. Special methods are required for sealing verification under special working conditions. Helium mass spectrometer leak detector is used to detect sealing performance under low-temperature working conditions, and water pressure test is used under ultra-high pressure working conditions (test pressure is 1.5 times the working pressure). If there is no leakage for 30 minutes, it is considered qualified. In safety prevention and control, a new step of "emergency adjustment for abnormal working conditions" has been added, such as immediately turning on the heating device and appropriately increasing the opening of the pressure reducing valve when a sudden drop in medium temperature is detected; When the outlet pressure suddenly increases by more than 10% of the rated value, the emergency relief valve is automatically triggered and the upstream shut-off valve is closed. After the adjustment is completed, 24-hour dynamic monitoring is required, recording pressure, temperature, and flow parameters every hour, and drawing parameter change curves to ensure stable operation of the equipment within the entire operating range. Operators need to receive specialized training, familiarize themselves with emergency response procedures under special working conditions, and avoid safety accidents caused by improper operation.

#Keywords: industrial use