详细介绍

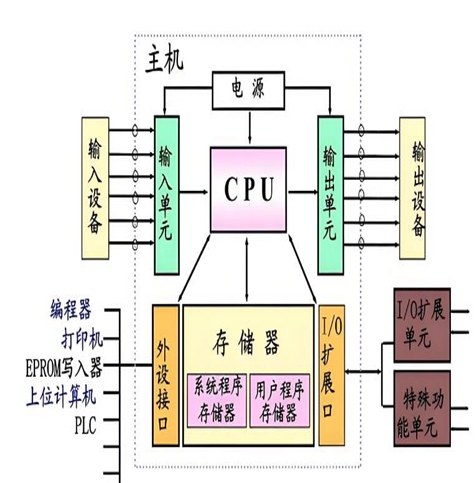

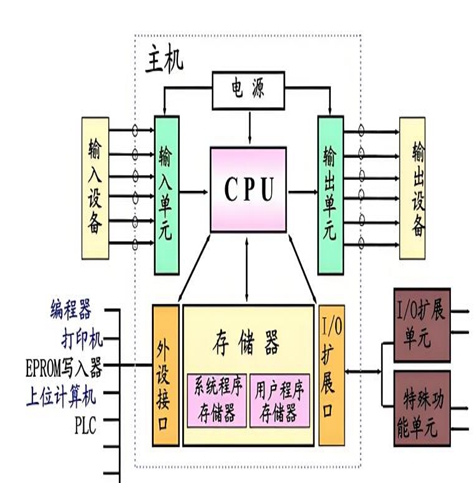

PLC 在过程自动化中的应用还体现在其能够实现复杂的控制算法和逻辑功能。它可以通过编程实现 PID 控制、模糊控制、自适应控制等先进的控制算法,对具有非线性、时变性和不确定性的过程对象进行有效的控制,提高过程控制系统的性能和稳定性。此外,PLC 还可以实现顺序控制、连锁保护等逻辑功能,确保生产过程的安全性和可靠性。0

The Important Application of Programmable Logic Controller (PLC) in Process Automation

In the field of process automation, programmable logic controllers (PLCs) also play an irreplaceable and important role, widely used in industries such as chemical, petroleum, power, and water treatment.

In the chemical production process, programmable logic controllers (PLCs) are used to control various parameters such as temperature, pressure, and flow rate of chemical reactions, ensuring that the reactions proceed under safe and stable conditions. For example, in the control of distillation columns in petrochemicals, PLC achieves the separation and purification of various components in the distillation column by adjusting parameters such as feed rate, reflux rate, and heating amount, ensuring that product quality meets standard requirements.

In the power system, programmable logic controllers (PLCs) are used for unit control in power plants, automation monitoring in substations, and scheduling management in the power grid. It can monitor the operating status of the generator in real time, control the excitation system and speed control system, and ensure the stability of the output voltage and frequency of the generator. At the same time, PLC can also control and monitor the switchgear and protection devices of the substation, achieving automated operation of the power grid and rapid fault handling.

In the water treatment industry, PLC is used for production process control in sewage treatment plants and water treatment plants. In the process of sewage treatment, PLC can control the operation of aeration equipment, water pumps, sludge treatment equipment, etc., achieving precise control of the biochemical treatment, sedimentation, filtration and other process links of sewage, ensuring that the effluent quality meets the discharge standards. In the water treatment plant, PLC can control the processes of raw water intake, purification, disinfection, etc., ensuring the quality and safety of water supply.

The application of PLC in process automation is also reflected in its ability to implement complex control algorithms and logic functions. It can implement advanced control algorithms such as PID control, fuzzy control, and adaptive control through programming, effectively controlling process objects with nonlinearity, time-varying, and uncertainty, and improving the performance and stability of process control systems. In addition, PLC can also achieve logical functions such as sequential control and interlock protection, ensuring the safety and reliability of the production process.